Moblie: 8613816755915

What is the Prefabricated quick assembly panelized Home

Prefabricated quick assembly panelized home system is a high-performance building system for residential and light commercial buildings. The traditional panel consists of two structural panels (usually OSB) ,The Solidhome has improved the traditional prefabricated quick assembly panelized home system, giving it more powerful load-bearing capacity and plasticity, replacing the original wooden edge with a more durable lightweight steel edge. The European pine board is replaced by a more mildew proof and waterproof magnesium oxychloride board / glass magnesium board. The insulation foam core is still used in the middle, and a new plate type quick assembly system is formed. Panels are manufactured under factory controlled conditions and are suitable for almost any architectural .

Advantages of the Prefabricated quick assembly panelized Home

Easy Installation

The most obvious advantage of the panelized home system is that it is much faster than other construction methods. Because the panels are already pre-fabricated and designed to fit together quickly and easily, the building process can be completed in a fraction of the time it would take to build a home using traditional methods. This makes it an ideal option for those who are looking to build a home quickly and cost-effectively.

Energy efficient

Another advantage of the panelized home system is that it is much more energy efficient than traditional construction methods. The panels used in the construction process are airtight, and the panels are closed off from each other by sealing strips means that they prevent air leaks and improve air quality, which helps to reduce energy costs. In addition, the panels also provide excellent insulation, which can help to reduce energy costs even further.

Aesthetic advantage

Panelized home systems also offer many aesthetic advantages over other prefab homes. The panels are exquisitely designed and stylish, and can be customized according to your own personal style, while other prefabricated houses cannot achieve the effect of paneled home system cornices due to the limitation of fixed dimensions . The panels can be designed to match the design and color of an existing home, blending the two seamlessly.

Strong structure

Panelized home systems are designed to be strong and durable. These panels consist of Rigid foam core with two layers of structural board, have superior structural performance to wood framed and steel framed walls . Under extreme conditions such as earthquake and wind , the seismic performance of the panel is better than other buildings. The panelized home system lasts longer than other prefab houses, at least guaranteed to last 70 years.

Assembly of panelized home

The installation sequence of panelized home is like this: bottom frame — wall panel — roof — garage.

1. Install the floor frame of the floor. After the floor supports positioning, use the horizontal meter to measure the horizontal point.

2. Install the fixed bolt on the wall panel, the bolt cover is covered on the fixed bolt, and the wall panel is slowly and parallel, until the wall panel is completely exposed to the floor. While the lock bolt is tightened, ensure that the wall surface is maintained vertically, which is convenient for subsequent wall panel installation.

3. Put the wall panel in order, and adjust the installation angle at the same time to ensure the vertical state of each wall panel until all wall panel are installed.

4. Install the roof Lugs and hang it parallel. When the roof drops to 100 m, wear a wire.

5. After wearing a wire, slow down the roof and fit the wall panel.

6, parallel hanging garage, put the pillar feet at the pillar pillar connection in turn. After installing it in turn, it drops to the ground contact.

7. Finally, the houses around the house are installed.

Elements of panelized home system

1. Patented fixing system, fast assembly mode, reducing labor costs

a. Wall: quick connection system between wall panels

b. Floor: adjustable height multi-platform floor system

c. Roof: large format quick connection system

2. Use large size panels

a. Glass magnesium board with GPS core

b. Dimensions: length 12 m, height 3.5 m

c. Wall: 120 mm exterior wall, 120 mm interior wall.

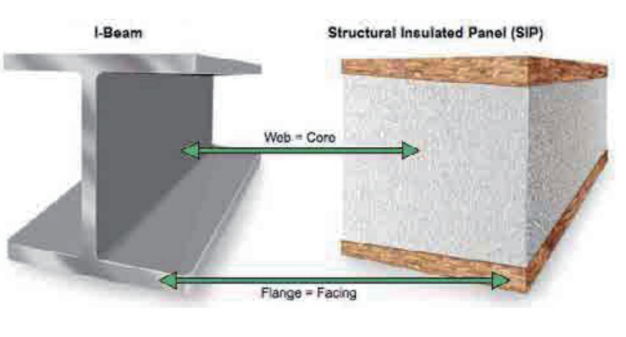

panelized home system—–Strength

1、Rigid foam core with two layers of structural board

2、MGO panels have superior structural performance to

wood framed and steel framed walls (up to 2X)

3、Share the same structural properties as L-Beams and

I-Beams

4、Under extreme conditions such as earthquake and

wind protection, the seismic performance of the panel is

better than that of other buildings.

Advantages of panelized home system

1、Allows for highly efficient CAM manufacturing

process

2、Rapid on-site installation

3、Improved building quality

4、Design flexibility

5、Superior structural performance with rigid building structures

6、High fire-ratings

7、Environmentally sustainable

8、Earthquake resistance and wind protection

9、Excellent thermal properties – 70% more energy efficient than conventional concrete and wooden

Panelized home system– Sound insulation

Two rows of 50×100 mm wooden keels are staggered between traditional walls, and sound-absorbing material (STC 55) is placed on one side.

Solidhome panelized home system can reach (stc 58-59).

The prefabricated panel has continuous insulation and fewer gaps to be sealed than traditional wood structure and light steel structure walls, so the sound propagates less through the gaps in the wall components.

The core of each component is a standard precast panel consisting of an insulating foam core (GPS) and two sides of the magnesium oxysulphide (MGO) skin. Directly connected to one side of the panel is 12 mm X-type gypsum wallboard. On the other side, a clip is screwed to the panel. Then clip the cap groove into the clip and fix 12 mm X-shaped plaster on the cap groove. The clip minimizes the contact area of each layer of the assembly, which helps to separate the assembly and reduce sound transmission, while providing sound insulation quality for the entire assembly. Additional sound insulation can be achieved by adding 60 mm glass fiber insulation to the space between the panel and gypsum generated by the clip. The components are non directional, so the clip system can be installed on either side of the wall preferred by the architect.